Plastic Dryer

Mold Temperature Controller

Auto Loader

Plastic Crusher

Plastic Mixer

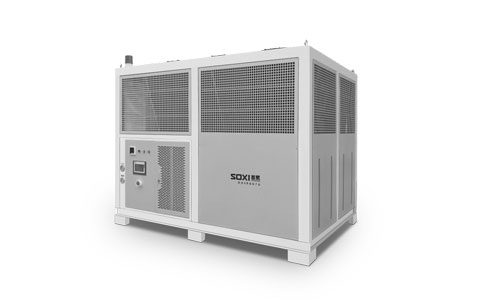

Indusrial Chiller

Automation System

Plastic Machinery Parts

Central Loading System

Central Water Supply System

Power Supply System

Purification System

Central Gas Supply System

Industrial Robot Integration Application

Intelligent Warehouse

Smart Injection Plant Complete Solution

Social activities of Guangdong SOXI Intelligent Equipment Co., Ltd.

Skill competition

Safety production emergency drill

Classification, Working Principles and Precautions for Common Vacuum Hopper Loade

What Are the Methods to Choose an Industrial Chiller?

The Development Trend of Plastic Dryer in the Next Few Years

Characteristics of Dehumidifying Dryer (Standard Type)

What is a Central Conveying System?

The Determinants of Drying Rate of Dehumidifying Dryer Material

The Difference between Dehumidifying Dryer and Ordinary Dryer

What Are the Structural Functions of the Injection Molding Machine?

Introduction to the Principle, Application Range and Characteristics of Hot Air Hopper Dryers

December employee birthday party

Working Principle and Operation of Plastic Moulding Machine

How Can the Mold Temperature Machine Be Cooled?

Classification of Plastic Moulding Machines

The Principle, Use and Classification of Plastic Crusher

How to Choose an Industrial Chiller?

Moulding Method of Plastic Moulding Machine

What is Central Conveying System?

Development Trend of Plastic Dryers in Next Few Years

Plastic Molding Methods for Central Conveying System

Pipeline Layout Requirements and Maintenance Methods of Central Conveying System

Classification, Working Principle and Attention Points of Common Vacuum Hopper Loader

The Difference Between Central Feeding System and Automatic Feeding System

How to Control the Water Volume of the Three-in-one Dehumidification Dryer?

Classification and Selection Skills of Dehumidification Dryers

What Should Be Paid Attention to in the Drying Gas Path of the Dehumidifying Dryer?

Three-in-one Dehumidifier and Dryer Humidity Measurement Method

What is the Function of the Various Accessories of the Dehumidifying Dryer?

What is the Difference Between a Plastic Dehumidifying Dryer and a Dehumidifying Dryer (Standard Type)?

Complete Solution for Central Conveying System

What is the Appropriate Temperature for the Dehumidifying Dryer?

What Do I Need to Do Before a New Dehumidifying Dryer Can Be Used?

Instructions for Use of the Dehumidifier Dryer (Standard Type)

Application Introduction of Industrial Chiller

Dynamic Heat Balance of Mold Temperature Machine: Mold Temperature Control is Essential

Plastic Shredder Machines Play an Important Role in Waste Plastic Recycling

What Details Should Be Paid Attention to when the Central Conveying System Fails?

Maintenance of High-pressure Fans for Central Conveying Systems

What Are the Factors That Affect the Price of Dehumidifying Dryers?

What is the Drying Temperature of the Dehumidifying Dryer?

Three Important Steps to Safely Operate Injection Molding Machines

Five Criteria for Mold Temperature Machine Selection

Why Use a Mold Temperature Machine?

Intelligent Central Conveying System to Help You Realize Intelligent Injection Molding Factory

The Conveying Principle of the Central Conveying System

Automatic Vacuum Hopper Loader is Widely Used in Industrial Development

Fault Detection and Troubleshooting Methods for Dehumidifying Dryer

Choose Dehumidifying Dryer according to Material.

Can Mold Temperature Machine Cool Down?

Drying Process of Dehumidification Dryer

The Application of Dehumidifying Dryer (Standard Type)

Precautions Before Using Dehumidifiying Dryer

Precautions of Using Heat Conducting Oil

Principle and Precautions of Dehumidifying Dryer

The Characteristics of High-pressure Blower with Central Conveying System

Composition of the Central Conveying System

Method of Using Central Conveying System and the Benefits of It‘s’ Installation

Measurement and Precautions of Dehumidification Dryer's Dew Point

How to Choose a High-Quality Central Conveying System?

Introduction to the Application of Industrial Chiller

How to Vent an Industrial Chiller?

Treatment and Functions of Dehumidifying Dryer (Standard Type)

Actual Steps for Using Industrial Chiller Unit

What Types of Dehumidifying Dryer Can Be Classified by Pressure?

Dehumidifying Dryer Dehumidification Mode and Working Principle

Advantages of Central Conveying System Planned for Injection Molding Workshop

Design Process and Characteristics of Central Conveying System

How to Quantify the Central Conveying System?

What Is the Importance of Central Conveying System Components?

What Problems Can the Central Conveying System Solve?

What Are the Reasons That Affect the Effectiveness of Dehumidifying Dryer?

What Are the Advantages of Central Conveying System Compared to Individual Feeding on the Machine?

What Is the Drying Method of Dehumidifying Dryer?

The Differences of Industrial Chiller Performance in Various Environments

Introduction to the Working Principle of a Dehumidifying Dryer (Standard Type)

How to Use the Mold Temperature Machine Correctly?

Search

English

English