What Is Plastic Auto Central Loading System?

As we all know, the rapid development of plastic production technology is a very broad application being used in this modern advanced science technology. Plastic auxiliary machinery's level of development and popularity is an important symbol of the national level in industrial development. In order to maintain an invincible position in this increasingly competitive market, a very important aspect is the use of advanced technology, the central loading system is the creature that has been maturely developed under this marketing needs.

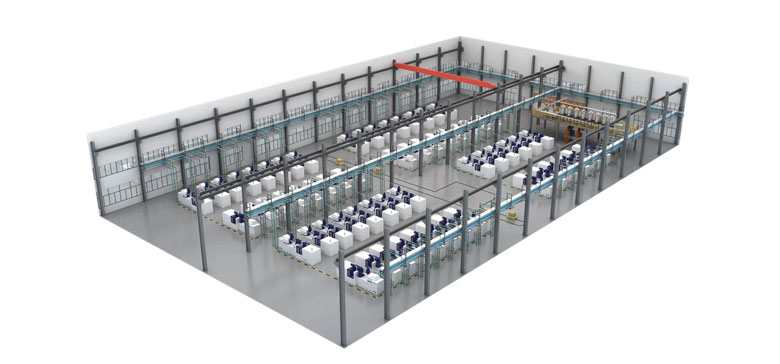

The central loading system is used in plastic production for concentrated loading and control so as to achieve continuous unmanned molding operation. The system can be modified according to different variables, by using a combination of multi-color materials, so as to achieve automatic mixing of raw materials, a small microcomputer metered mixer to control the coloring process of each molding machine and accurate measurement, even mixing, and the flexibility in changing colors, to suit the multi-colors varieties of the product. The system can flexibly adjust the loading supply in accordance with different types of molding machines. Multiple feed pipes are designed to ensure the demands of diversification of raw materials. The system consists of a variety of monitoring and protection functions that are safe and reliable.

The system can fully be automated manner by using a robotic arm and an ancillary mechanical crusher to achieve a proportionate virgin and degraded materials recycling thus saving raw materials, reducing labor cost, increasing production capacity, and greatly reducing the production cost by providing a fully automated central monitoring station.

The central loading system adopts the vacuum frequency transmission, the raw materials are transported from the storage tank to the centralized drying zone by utilizing the centralized pipeline transportation system. The dried raw material is then conveyed to the hopper on the molding machine. Pipeline transportation system adopts a variety of designs, such as" a machine with a pipe" "a machine double pipes", "one or more material pipe" "a machine with a pipe+ material pipe" and "multi-material pipe with cut-off valve" which can be designed according to your company's material conditions. Stability of the system is ensured and no blocking of the material will occur, centralized drying of the raw materials, using dry air to convey the dried materials so as to prevent it from being humidifying.

English

English